Introduction

In the realm of mineral processing, the fine sand recovery process stands as a critical operation, aimed at maximizing recovery rates while ensuring the sustainable utilization of resources. The project harnessed NiaFlow’s software to design and simulate the fine sand recovery process in a comprehensive and efficient manner. By harnessing NiaFlow’s capabilities, the project team was able to execute a comprehensive simulation, analysis, and optimization of the process flowsheet, showcasing the software’s robustness in enhancing operational efficiency.

Project Overview

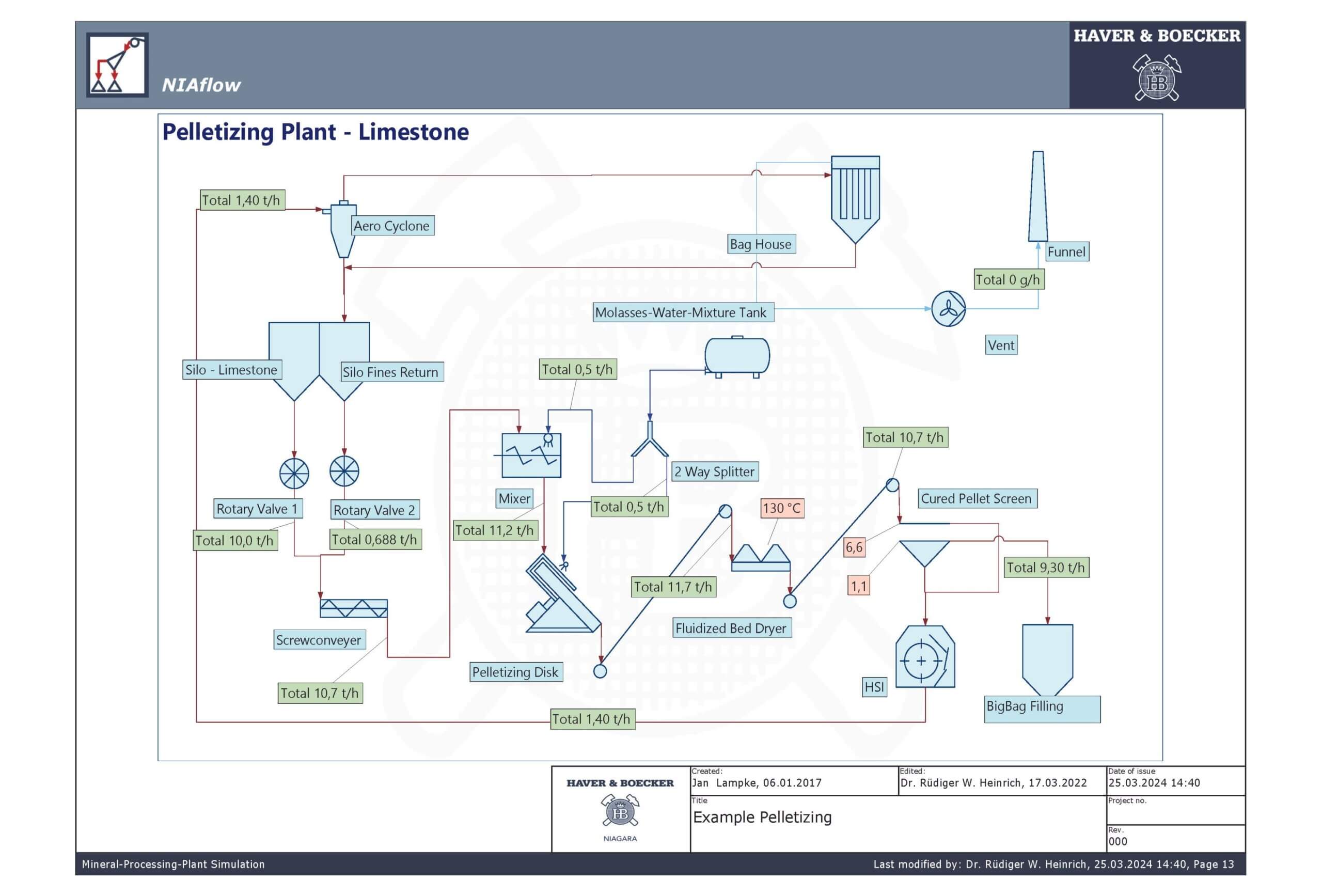

The project centered on the recovery of fine sand from a total material throughput of 200 tons per hour, with an impressive recovery rate showcasing the efficiency of the process design. NiaFlow’s detailed simulation provided insights into the machinery sizing, mass balance, and water consumption, ensuring optimal equipment selection and process flow.

Key to the project was NiaFlow’s capability to provide a granular analysis of each component within the process, including the technical specifications of equipment (e.g., screens, sorters), operational parameters (e.g., throughput rates, water content, particle size distribution), and overall system performance metrics. This granularity extended to the simulation of environmental conditions and operational parameters, enabling a holistic view of the process under various scenarios.

Key equipment used in the process included a variety of components such as screens, sorters, pumps, and water taps, precisely calibrated for maximum performance. For instance, the Upstream Sorter – Coarse Sand Unit and the Upstream Sorter – Fine Sand Unit played crucial roles in separating fine particles, demonstrating NiaFlow’s capability in handling complex separations.

NiaFlow’s Capabilities Highlighted

- Define Printouts and Customization: The project leveraged NiaFlow’s advanced customization features for documentation, enabling the creation of tailored printouts for both the flowsheet and project summary. This facilitated clear communication of complex data and operational insights to stakeholders, enhancing project transparency and decision-making processes.

- Calculations: The simulation offered a comprehensive mass balance analysis, revealing the distribution and flow of solids and water throughout the process. This level of detail enabled the team to optimize the water usage and recycling within the system, significantly enhancing sustainability and efficiency.

- Documentation: Utilizing the label layer function, the project team was able to print the flow sheet with varying depths of information, providing stakeholders with a clear understanding of the process operations and the role of each component within the system. The comprehensive project print feature offered a detailed summary of all plant and object data, including equipment lists and a project history. This feature was crucial in documenting the project lifecycle and ensuring a thorough review of operational parameters and outcomes.

- Simulation and Analysis: At the heart of NiaFlow’s contribution was its powerful simulation engine, enabling the project team to model the fine sand recovery process with high accuracy. The software’s analysis tools allowed for the identification of bottlenecks and inefficiencies, guiding the optimization efforts to improve recovery rates and operational efficiency.

Conclusion

The application of NiaFlow in the fine sand recovery project underscores the software’s versatility and effectiveness in optimizing mineral processing operations. Through detailed simulation, customization, and analysis capabilities, NiaFlow facilitated a comprehensive understanding and enhancement of the fine sand recovery process. This case study exemplifies NiaFlow’s role as a pivotal tool in advancing operational efficiencies and sustainability in mineral processing endeavors. Through precise equipment sizing, detailed mass and water balance analyses, and environmental adaptability, NiaFlow proved to be an invaluable tool in fine sand recovery projects.

This case study serves as a testament to NiaFlow’s capabilities in documenting and optimizing complex mineral processing operations, providing engineers and project managers with a powerful tool for enhancing operational outcomes and sustainability.