Introduction

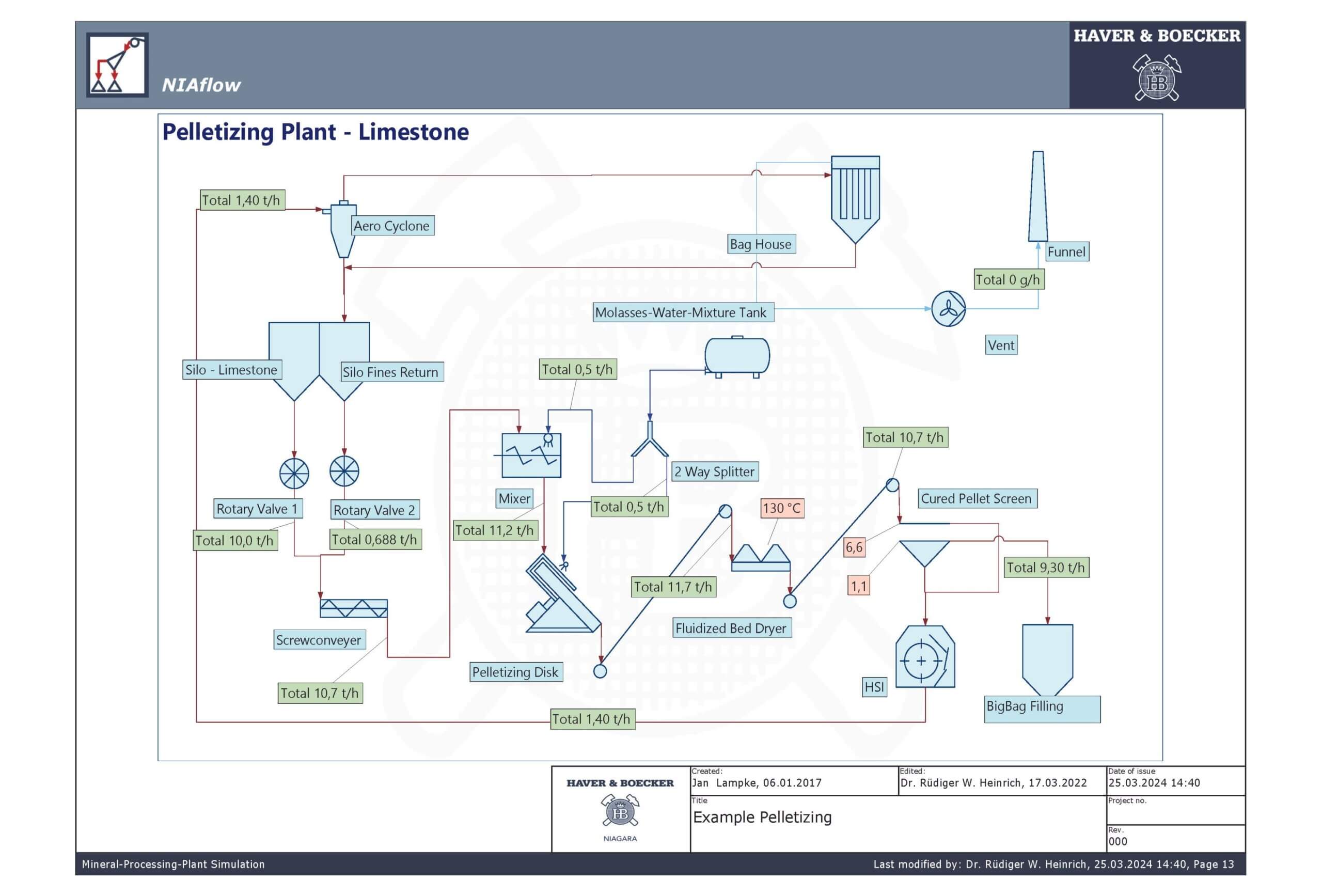

In the field of mineral processing, the selection of appropriate screen media plays a critical role in optimizing the efficiency and effectiveness of screening operations. A case study conducted using the NiaFlow simulation software exemplifies the innovative approach towards evaluating the performance of four different types of polyurethane screen media for a vibrating screen, specifically the T-CLASS S 2400×7000 3D model. This study aimed to simulate the processing performance of these screen media to inform decision-making in screen media selection.

Approach

The analysis encompassed four options of screen media, with each option presenting distinct characteristics and performance metrics. The simulation evaluated parameters such as throughput capacity (measured in tons per hour), particle size distribution, and screening efficiency across the different screen media options.

- Option 1 involved a combination of Ty-Groove panels and HAVER square mesh, achieving a total throughput of 843 tons per hour with a notable efficiency in particle size distribution, demonstrating a wide range of applicability from fine to coarse materials.

- Option 2 replicated the configuration of Option 1, providing consistent performance metrics and reinforcing the reliability of the Ty-Groove and HAVER square mesh combination.

- Option 3 and Option 4 followed suit in employing the same screen media configurations, with their performance outcomes echoing the effectiveness of the previously mentioned options. These results solidify the understanding of how different screen media affect the screening outcomes.

The study’s findings illustrate the utility of the NiaFlow simulation in providing a detailed comparison of screen media performance. By leveraging NiaFlow’s comprehensive simulation capabilities, stakeholders can make informed decisions on screen media selection based on empirical data. This approach not only enhances the operational efficiency of mineral processing plants but also contributes to the optimization of resource utilization and reduction of operational costs.

The case study underscores the NiaFlow software’s capabilities in simulating complex mineral processing operations, offering a robust tool for engineers to model, analyze, and optimize screening processes. The meticulous analysis of screen media performance through simulation exemplifies a forward-thinking methodology that combines technological advancement with practical applications in the mineral processing industry.